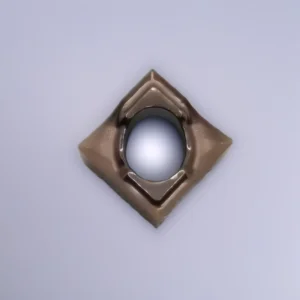

Product Details

- Application – It is applicable to the semi-finishing and finishing machining of side milling, face milling, and R-angle contour milling for steel after quenching with a hardness of HRC 48 – 52°.

- Substrate – This end mill is made of nano-grained tungsten carbide, which significantly improves wear resistance and greatly prolongs the tool life.

- Coating – The PVD coating equipment from Kobe Steel in Japan has been introduced, and a multi-layer composite coating is adopted to ensure the high stability and high-efficiency performance of the coating.

- Precision – Our products offer excellent precision. The accuracy of rounding and ball nose R is controlled within ±0.005 mm, the contour accuracy is ±0.005, and the shank diameter tolerance is at the h5 grade.

Processing Scenario

- Milling method: Side Milling, Semi-Finishing

- Spindle speed: 9500 RPM

- Feed rate: 1500 mm/min

- Cutting depth: 4 mm

- Cutting width: 0.05 mm

- Cooling method: Water Cooling

- Testing machine: Makino F3

- Workpiece material: S136 Steel (Material Hardness: HRC 51.5)

Test Result

The performance of our company’s product D4R0.5*11H*D4*50L*4F-HS is consistent with that of the competing product of the ZZ brand.

Reviews

There are no reviews yet.