Summary:

Stainless steel is known for its toughness and resistance to corrosion, making it one of the most demanding materials to drill through. For businesses and professionals dealing with stainless steel regularly, choosing the right drill bit is crucial for maintaining efficiency, reducing downtime, and avoiding costly tool breakage. This article explores the best drill bits for stainless steel, providing a comprehensive overview of the options available, their features, and how to maximize performance. With data-driven insights and practical advice, it aims to guide buyers, wholesalers, and users in making informed decisions when selecting drill bits for stainless steel.

1. Why Stainless Steel Demands Special Drill Bits

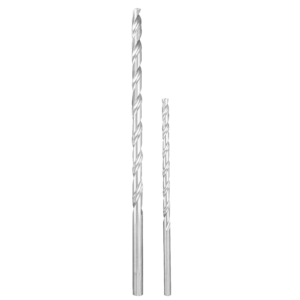

Stainless steel is known for its hardness and resistance to wear, which makes drilling through it challenging. The Brinell hardness of stainless steel can range from 170 to 220, depending on the alloy, which is significantly higher than softer metals like aluminum or mild steel. Standard drill bits, made of high-speed steel (HSS), often wear out quickly when used on such tough materials.

To ensure efficient drilling and avoid breakage, it’s essential to use drill bits specifically designed for stainless steel. These bits are typically made from higher-grade materials such as cobalt, carbide, or HSS with special coatings. These materials are much more resistant to the high heat and pressure generated during the drilling process, ensuring longer tool life and better performance.

2. Materials Matter: The Best Drill Bits for Stainless Steel

When choosing drill bits for stainless steel, the material of the bit is a critical factor in determining performance and longevity. The three most popular materials for stainless steel drill bits are:

Cobalt Drill Bits: These bits contain a percentage of cobalt, which significantly enhances their heat resistance. Cobalt drill bits are a popular choice for drilling through hard stainless steel grades like 304 or 316, as they maintain their sharpness longer than traditional HSS bits. With a high cobalt content, these bits can withstand temperatures up to 1,100°F (593°C), making them ideal for tough applications.

Carbide Drill Bits: Carbide is one of the hardest materials available, and carbide drill bits are perfect for precision drilling in stainless steel. These drill bits can withstand extremely high temperatures and wear, ensuring excellent cutting performance over extended periods. However, carbide bits are brittle, so they should be used with caution in high-impact applications.

High-Speed Steel (HSS) Drill Bits: Standard HSS drill bits are the most common option for general-purpose drilling. For stainless steel applications, it is recommended to use HSS with a coating, such as titanium nitride (TiN), to improve hardness and wear resistance. These drill bits can drill through stainless steel but may wear out quickly if not used with proper speed and pressure.

3. Drill Bit Coatings and Their Benefits

While the material of the drill bit is crucial, coatings also play a significant role in enhancing performance and reducing breakage. Common coatings for drill bits used on stainless steel include:

Titanium Nitride (TiN) Coating: TiN-coated drill bits are known for their durability and resistance to wear. The coating increases hardness and provides an excellent barrier against corrosion, making them ideal for drilling through stainless steel. TiN coatings extend the life of the drill bit by reducing friction and heat buildup, which are common causes of premature wear and breakage.

Titanium Carbonitride (TiCN) Coating: This coating is harder than TiN and provides superior wear resistance, making it ideal for more demanding stainless steel drilling applications. TiCN-coated bits perform better at higher speeds and offer improved cutting capabilities.

Black Oxide Coating: While not as durable as TiN or TiCN, black oxide coatings can still improve the lifespan of standard HSS bits. These coatings reduce friction and prevent corrosion, which is especially important in stainless steel applications where the material’s hardness can wear down uncoated bits quickly.

4. Optimal Speed and Pressure for Drilling Stainless Steel

Using the right drill speed and pressure is crucial when working with stainless steel to avoid overheating and drill bit breakage. Drilling at excessive speeds can cause the bit to overheat and lose its sharpness, while too much pressure can lead to tool damage.

Speed: The optimal speed for drilling stainless steel varies based on the drill bit material and size. For cobalt and HSS coated bits, a range of 600 to 1,200 RPM is recommended, depending on the diameter of the bit. Carbide bits, however, can handle higher speeds but should be used with care due to their brittleness.

Pressure: Apply moderate, consistent pressure when drilling. Too much force can cause the drill bit to break or wear out quickly, while too little pressure may result in inefficient drilling. Let the drill bit do the work, maintaining a steady, controlled feed rate.

5. Drilling Tips for Success

To maximize the lifespan of your drill bits and ensure high-quality results, consider the following tips:

Lubrication: Using a cutting fluid or lubricant specifically designed for stainless steel can help reduce friction and heat buildup during the drilling process. Lubrication also helps in chip removal, preventing clogs that can damage the bit.

Multiple Stages for Larger Holes: For larger holes, use a step drill process, starting with smaller bits and gradually increasing the size. This technique reduces the strain on each individual bit and ensures cleaner holes.

Cooling: If drilling deep holes, stop periodically to allow the drill bit to cool down. Continuous operation without cooling can lead to overheating and premature failure.

What is the best drill bit for drilling through hard stainless steel?

Can I use regular HSS drill bits for stainless steel?

How do I prevent drill bit breakage when drilling stainless steel?

Why should I use a TiN-coated drill bit for stainless steel?

What speed should I drill at when working with stainless steel?

Conclusion

Choosing the right drill bits for stainless steel is essential for achieving high-quality results and minimizing downtime due to tool breakage. Whether you opt for cobalt, carbide, or HSS-coated drill bits, understanding the material, coating, and appropriate drilling techniques is crucial for success. By selecting the best drill bits for stainless steel, you can ensure that your projects run smoothly, saving time and money while delivering excellent performance every time.