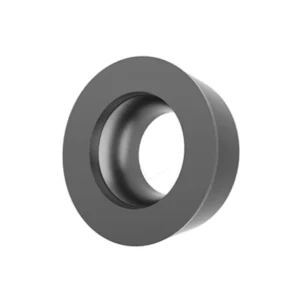

Product Details

- Application – Applicable to the rough machining and semi-finishing machining of side milling for common steel, cast iron, and quenched steel, as well as face milling and contour milling when the hardness is below HRC 55°.

- Substrate – The newly upgraded substrate is ultrafine, characterized by high wear resistance and high hardness, making the inserts more durable.

- Coating – The brand-new “multi-layer composite” coating with high hardness, high temperature resistance, and wear resistance perfectly matches the substrate and is invincible in the processing of hardened steel.

Processing Scenario

- Milling method: Rough Face Milling

- Spindle speed: 2200 RPM

- Feed rate: 2000 mm/min

- Cutting depth: 0.15 mm

- Cutting width: 12.6 mm

- Tool shank diameter: D21R0.8

- Cooling method: Water Cooling

- Testing machine: Zhenlong 850

- Workpiece material: S136 steel (Material Hardness: HRC 51.5)

Test Result

The APMT1135A-DL-champagne high-hardness inserts have surpassed the lifespan of the domestic well-known brand RW-1135 by 16.6% in this test.

Reviews

There are no reviews yet.